Print and Apply labelling is an important part of your manufacturing and logistics process. Effective labelling will help you ensure a smooth production process and put traceability at the forefront of your operations. There are various Print and Apply labelling options available, all easy to use, offer a low cost of ownership and are extremely efficient.

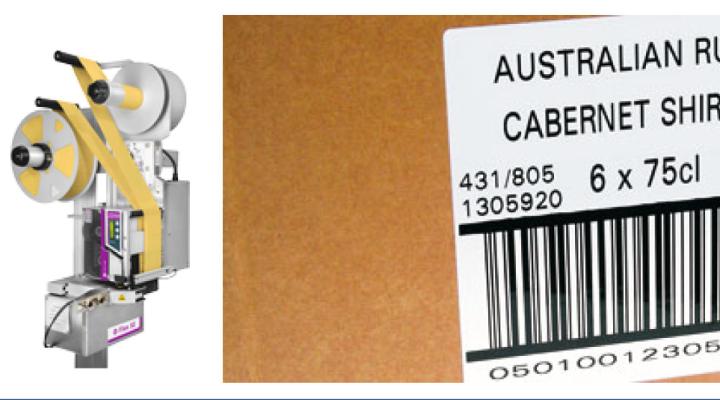

With Print and Apply labelling, it lets you create and apply labels directly onto products and packaging. The labels carry data including barcodes, serialisation alphanumeric text, 2D codes, QR codes and more.

As channel partner for Markem-Imaje, here at Industrial Printer Services Ltd we are able to supply the most up to date Print and Apply technologies to increase the efficiency of your processes. By using Markem-Imaje’s 2200 series print and apply labelling technology it’ll help you become more efficient by reducing labour costs, minimising human error, help reduce reruns, and give you more time to focus on meeting the needs of core areas of your business.

GS1 compliance is a crucial aspect of Print and Apply labelling. For example, in the FMCG sector, Serial Shipping Container Codes (SSCCs) for pallets, and GS1-128 codes for cases, need to be applied and read and scanned successfully. This is also becoming increasingly important in the Pharmaceutical industry where item level serialisation means that Print and Apply labelling technologies are now even more important. Markem-Imaje’s 2200 series Print and Apply labellers meet the full GS1 supply chain specifications.

Depending on the substrate you wish to apply your labels you’ll need to use different techniques. If your surface is uneven it certainly creates issues, but the Markem-Imaje 2200 series Print and Apply labeller offers a range of application methods. Blow and Tamp methods can be used, the blow method is best for fragile or odd shaped substrates. Rugged surfaces can be labelled by using a press on pad called a tamp application.

The size of the label is measured by width and length, and it is important to check and identify the size of the label needed in terms of the space available. Secondly, think about the application that suits your circumstances and substrate the best. There are four methods:

The Markem-Imaje 2200 series is designed to integrate into diverse production line layouts, with left- and right-hand versions, and can be mounted at different angles. This means you are empowered by flexibility and integration into your manufacturing environment.

The Markem-Imaje Print and Apply labelling technology that we supply here at Industrial Printer Services Ltd is made to offer multiple options for where the label can be placed on the product. The labels can be printed and applied to the front, back, top, bottom, side or over corners. They also offer the ability to apply multiple labels on a single substrate.

The integration of Print and Apply technology with your production line is a crucial consideration. The labeller will need to accommodate the location of the product, case or pallet that is being labelled as it passes through. Not only that, it must be small enough to fit into the available physical space on your production line.

The Print and Apply technology that we supply here at Industrial Printer Services Ltd has been designed to work efficiently in the smallest of production environments. With a site visit to assess your production line, define your requirements and check the factory environment ensures the optimum print and apply labelling solution is installed.

You have read this far, now you are wondering why you should really invest in this technology - what are the real benefits to my business…

When considering the advantages of print and apply labelling technology, the first thing to identify is how much faster and reliable it is compared with a manual process. The potential for errors is minimised, so is wastage, labour costs, and all this means less costs and more profit for your business.

The technology we supply is made to be integrated within your production line, and the speed of automated labellers can bring many benefits. They remove the need for employees to manually print and stick labels, reducing downtime and wastage. It also increases the ability to reallocate workers to more valuable operations within your business. There is no need to stockpile labels, your labels will be able to be printed on demand.

With ever increasing importance being put on traceability and efficiency within the supply chain, the demand for labelling automation systems will continue to increase.

If you would like more help, guidance or information on Print and Apply labelling technology Contact us today and we’d be more than happy to talk you through the best solution for your business.